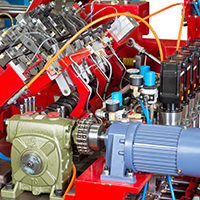

BOLT PARTS FORMER

BOLT PARTS FORMER

FEATURE

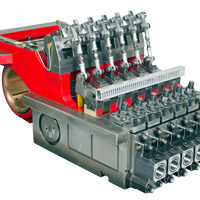

5 & 6 station bolt parts former are able to forge special bolt parts, these models emphasize about higher precision, higher forging power and wide die size range for more different shape special bolt parts.

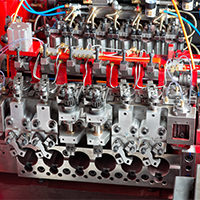

P.K.O ADJUSTABLE SYSTEM

Each mold can adjust the length and time of P.K.O

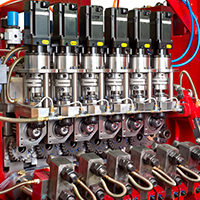

RAM ADJUSTING SLIGHTY DIGIYTAL HANDWHEEL

The digital handwheel will control the main slide to forward and backward, it can do die calibration and transfer adjustment.

UNIVERSAL ROTARY TRANSFER MECHANISM

Billet can be rotary for complex forming.

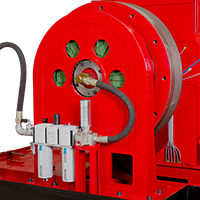

INVERTER+CLUTCH

The continuously variable transmission and air pressure brake system will make opreation easily.

K.O. LENGH ADJUSTMENT BY SERVO MOTOR

The servo motor could control the length of billet in the die side.

AUTOMATIC ELEVATING TRANSFER

Installing the motor to drive the chain for elevating transfer.

STOPPER LENGHT ADJUSTMENT BY SERVO MOTOR

The servo motor could control the length of billet in the punch side.

WIRE FEEDING LENGTH ADJUSTMENT BY SERVO MOTOR

The servo motor could control wire feeding length.

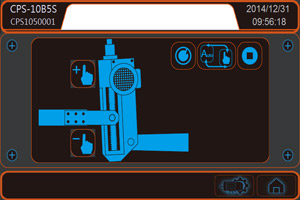

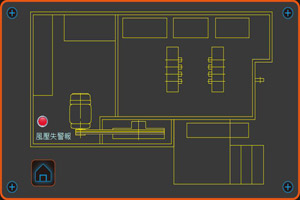

The human machine interface was developed by CCM 's R&D team, it could be flexible adjustment depend on customer's request.

Human Machine Interface

Wire Feeding, Stopper, K.O.

Operated by Graphical Panel

Wire Feeding, Stopper, K.O.

Operated by Graphical Panel

Wire Feeding, Stopper, K.O.

Operated by Graphical Panel

Operation Panel

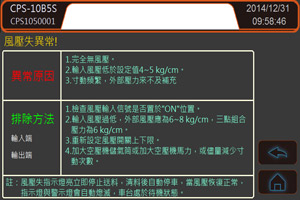

Abnormity Removing

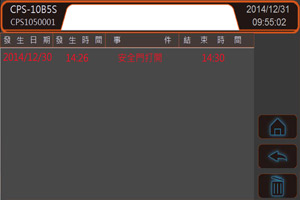

Error Log

Abnormity Indication

CPS & CPD SERIES 5 &6 STATION BOLT PARTS FORMER

| MODEL | CPD-10B | CPS-10B | CPS-13B | CPS-17B | CPS-19B | CPS-24B | CPS-30B | CPS-36B | CPD-13B6SL |

|---|---|---|---|---|---|---|---|---|---|

| SPECIFICATION | |||||||||

| FORGING STATION | 5 | 6 | 5 6 | 5 6 | 5 6 | 5 6 | 5 6 | 5 6 | 6 |

| CUT-OFF DIA MAX(mm) | 12 | 12 | 15 | 17 | 19 | 23 | 30 | 34 | 16 |

| CUT-OFF LENGTH MAX(mm) | 120 | 100 | 110 | 140 | 165 | 200 | 250 | 280 | 180 |

| KICK-OUT LENGTH MAX(mm) | 110 | 80 | 85 | 120 | 145 | 175 | 220 | 260 | 170 |

| P.K.O LENGTH MAX (mm) | 25 | 25 | 25 | 30 | 35 | 45 | 45 | 50 | 30 |

| MAX .CHUCK TURN LENGTH (mm) | 25 | 25 | 40 | 40 | 60 | 70 | 100 | 120 | 40 |

| CUT-OFF QUILL (D X L) (mm) | 40×60 | 40×60 | 50×80 | 50×80 | 60×100 | 75×100 | 95×120 | 110×155 | 50×80 |

| MAIN DIE HOLE (D X L) (mm) | 50×130 | 50×130 | 70×135 | 80×150 | 95×175 | 108×200 | 125×240 | 155×280 | 70×185 |

| DIES PITCH (mm) | 69 | 69 | 87 | 93 | 114 | 126 | 138 | 174 | 87 |

| PUNCH HOLE (D X L) (mm) | 40×110 | 40×110 | 50×120 | 50×120 | 65×150 | 75×180 | 90×220 | 110×240 | 50×130 |

| RAM STROKE (mm) | 150 | 150 | 190 | 200 | 240 | 280 | 360 | 400 | 250 |

| FORGING POWER (ton) | 55 | 65 | 100 135 | 140 170 | 185 220 | 220 260 | 300 400 | 460 550 | 110 |

| MAX. OUTPUT (pcs/minute) | 160 | 160 | 130 | 120 | 110 | 90 | 65 | 60 | 120 |

| MAIN MOTOR (hp) | 20 | 25 | 30 40 | 40 50 | 75 75 | 100 100 | 125 125 | 150 175 | 50 |

| APPROX.WT.(ton) | 14 | 16 | 17 19 | 24 27 | 38 43 | 60 65 | 77 85 | 115 128 | 26 |