HIGH PERFORMANCE FORMER

HIGH PERFORMANCE FORMER

FEATURE

The bolt former has is high performance, precision and stability. Max out put 400pcs/min. in same space and double production capability.

OPTIMIZED CUT-OFF KNIFE

Optimized cut-off knife as square shap, the material of cut-off knife is special aluminum alloy which will avoid the sway problem for cutting operation.

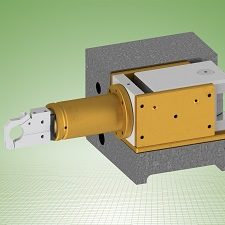

HEAVY SLIDER

The main slider equips with the heavy slider to stabilize the bolt former to avoid the vibration issue under the high speed operation.

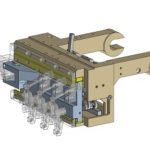

LIGHTWEIGHT TRANSFER

The material of lightweight transfer is aluminum alloy which is low density and high strength. We also use wear resistant steel for main slider to reduce wear issue.

OIL FILTER

Installing high efficiency centrifugal filter to keep clean inside the bolt former. The filter brand is MANN+HUMMEL from Britain.

MACHINE INDIDE

The feeding system is one-way bearing to avoid the material returning.

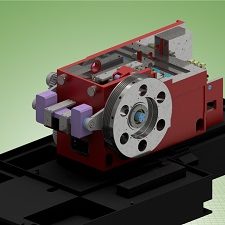

CLUTCH

The clutch is Japanese brand. The feature is lower air current request, but producing high torsion, therefore, the clutch could bear higher transmission power.

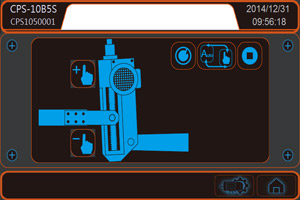

The human machine interface was developed by CCM 's R&D team, it could be flexible adjustment depend on customer's request.

Human Machine Interface

Wire Feeding, Stopper, K.O.

Operated by Graphical Panel

Wire Feeding, Stopper, K.O.

Operated by Graphical Panel

Wire Feeding, Stopper, K.O.

Operated by Graphical Panel

Operation Panel

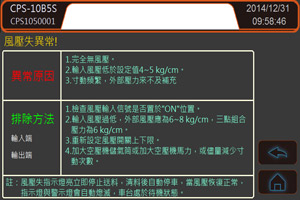

Abnormity Removing

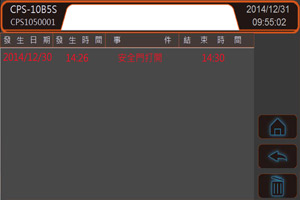

Error Log

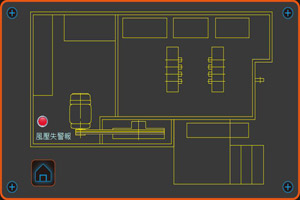

Abnormity Indication

CHS SERIES 3&4 STATION FORMER

| MODEL | CHS-10B | CHS-13B | CHS-17B | CHS-19B | CHS-24B | CHS-30B | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SPECIFICATION | ||||||||||||||

| FORGING STATION | 3 | 4 | 3 | 4 | 3 | 4 | 3 | 4 | 3 | 4 | 3 | 4 | ||

| PRODUCTS | SIZE | 1/4 (M6) | 5/16(M8) | 3/8(M10) | 1/2(M12) | 5/8(M16) | 3/4(M20) | |||||||

| MAX.L(mm) | 50 | 70 | 100 | 125 | 150 | 200 | ||||||||

| MIN.L (mm) | 12 | 16 | 16 | 20 | 25 | 40 | ||||||||

| CUT-OFF DIA MAX(mm) | 8 | 10 | 12 | 15 | 18 | 23 | ||||||||

| CUT-OFF LENGTH MAX(mm) | 70 | 95 | 125 | 165 | 190 | 260 | ||||||||

| KICK-OUT LENGTH MAX(mm) | 60 | 80 | 110 | 145 | 175 | 235 | ||||||||

| P.K.O LENGTH MAX (mm) | 14 | 20 | 25 | 25 | 30 | 35 | ||||||||

| CUT-OFF QUILL (D X L) (mm) | 28×46 | 35×56 | 40×60 | 46×80 | 60×100 | 75×120 | ||||||||

| MAIN DIE HOLE (D X L) (mm) | 50×65 | 70×115 | 80×135 | 95×165 | 100×195 | 135×260 | ||||||||

| DIES PITCH (mm) | 60 | 87 | 93 | 114 | 126 | 150 | ||||||||

| PUNCH HOLE (D X L) (mm) | 40×77 | 50×118 | 50×111 | 60×120 | 75×165 | 90×197 | ||||||||

| RAM STROKE (mm) | 120 | 140 | 160 | 240 | 280 | 360 | ||||||||

| FORGING POWER (ton) | 20 | 30 | 40 | 50 | 55 | 75 | 80 | 100 | 140 | 170 | 200 | 220 | ||

| MAX. OUTPUT (pcs/minute) | 400 | 350 | 280 | 250 | 165 | 120 | ||||||||

| MAIN MOTOR (hp) | 20 | 25 | 30 | 30 | 40 | 50 | 60 | 75 | 100 | 100 | 125 | 125 | ||

| MODEL | Productitive (pcs/min) |

|---|---|

| STANDARD FORMER | 200~250 (PCS /MIN) |

| HIGH PERFORMANCE FORMER | 350~400 (PCS /MIN) |